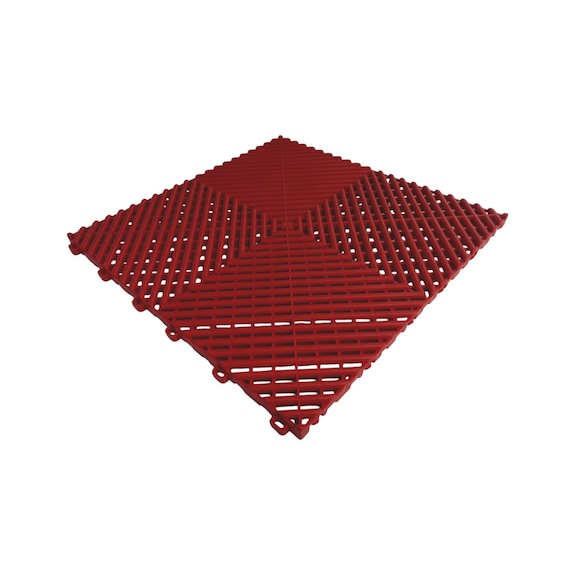

Modular Workshop Flooring - Tiles & Edging

Perforated workshop floor mat

FLRMAT-VENTED-RED-TILE

Art.-no. 0957034020

EAN 4068362267857

Register now and access more than 6,000 products

The modular workshop flooring system is the ideal solution for creating a safe, durable, and professional workspace. With interlocking tiles, edging, and corner pieces, it delivers a seamless finish that is tough, slip-resistant, and ergonomic. Built to withstand the demands of workshops, garages, and industrial areas, it installs quickly without tools and provides long-lasting performance in even the harshest conditions.

- Before installation, carefully calculate the floor size and the number of tiles required. Each tile connects seamlessly, and layouts should be planned in advance to avoid shortages.

- Ensure you also calculate the correct number of edging strips (male/female) and corner pieces to achieve a safe, professional finish without exposed edges.

- Specifications provided are based on installation on a clean, flat, and level surface. Uneven or sloped floors may affect performance and alignment.

- Tile measurements are given per unit; examples include: 1 tile, 4 tiles (2 × 2), and 25 tiles (5 × 5). These examples are intended for planning purposes only, always calculate according to your specific floor area.

- The flooring system is intended for workshop, garage, and industrial environments. It is not designed for food preparation, medical, or highly sensitive environments.

- Regular cleaning and inspection are recommended to maintain slip resistance, ergonomic benefits, and durability.

- Installation is tool-free; however, tiles must be firmly clicked into place to ensure stability and safety.

Datasheets(X)

The modular workshop flooring system is designed for use in demanding environments where safety, durability, and comfort are essential. Typical applications include:

- Automotive workshops – service bays, mechanic areas, tool zones

- Garages – private or commercial vehicle storage and repair spaces

- Industrial workstations – production floors, machine operator zones

- Warehouses & logistics – walkways, packing areas, loading stations

- Service & maintenance areas – aircraft hangars, agricultural equipment bays, and heavy machinery workshops

Step 1: Surface Preparation

- Ensure the floor is clean, flat, and level.

- Remove dust, oils, and debris before installation.

- Note: Uneven surfaces can cause poor interlocking and reduce stability.

Step 2: Layout Planning

- Each tile has 2 male sides and 2 female sides, placed adjacent, not opposite.

- Plan the layout so that tiles always connect male to female.

- Begin planning from one corner of the area to minimise cutting or mismatched edges.

- Note: Pre-planning helps avoid gaps and ensures edging fits correctly later.

Step 3: Tile Installation

- Start in one corner and place the first tile.

- Work outward row by row, locking tiles together by pressing or lightly tapping into place.

- Check alignment frequently to keep the layout square.

- Note: Once connected, tiles form a stable surface without the need for adhesives.

Step 4: Adding Edging

- After tiles are fully laid, add edging where required to finish open sides.

- Match the edging to the tile side:

- Male tile side → Female edging

- Female tile side → Male edging

- Press edging firmly into place to lock it.

- Note: Edging provides a bevelled slope, reducing trip hazards and ensuring a professional finish.

Step 5: Installing Corners

- Use corners at exposed edges to round off the flooring system.

- Corners connect only to edging, not directly to tiles.

- All corners are female, and both edging types (male and female) have female sides for corner connection.

- Note: Corners ensure a neat, safe finish at transitions.

Step 6: Final Check

- Walk across the flooring to ensure all connections are locked securely.

- Adjust any loose sections before use.

- Note: Regular cleaning and inspection are recommended to maintain slip resistance, durability, and appearance.

Design | Perforated, Slitted, Impact-resistant, Male/female |

Length x width x thickness | 400 x 400 x 20 mm |

Colour | Red |

Material | Polypropylene modified |

Min./max. temperature resistance | -20 to 80 °C |

Product weight (per item) | 560.000 g |