For detailed information, other images and documents, please select individual articles from the following table.

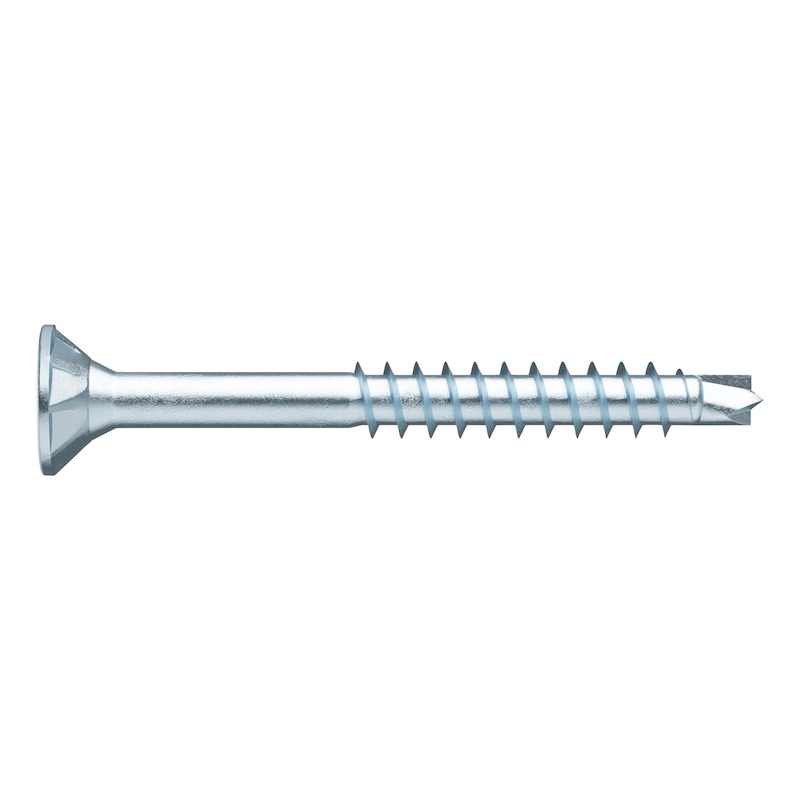

ASSY®plus 4 CSMP universal screw Hardened zinc-plated steel, partial thread, countersunk milling pocket head

Universal partial thread with countersunk head with milling pockets. Suitable for gap-free attachment close to edges without pre-drilling of wood-wood connections in indoor dry or sheltered areas.

Register now and access more than 6,000 products

Variants

Register now and access more than 6,000 products

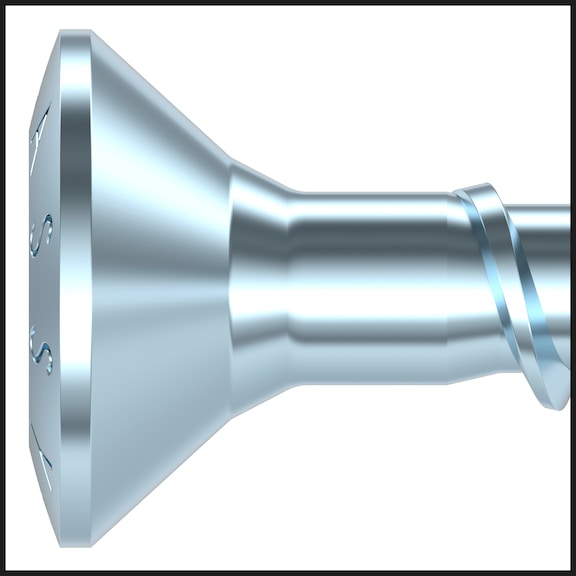

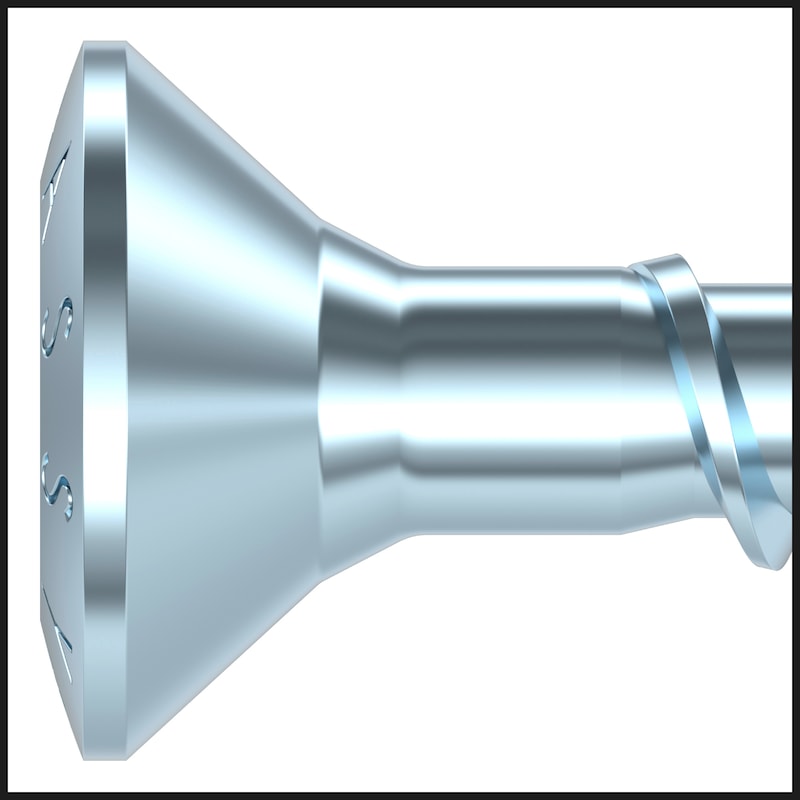

Ideal power transmission thanks to RW drive

- More power due to larger contact area at the bit

- More stability, one-handed working, precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for many screw diameters

- Compatibility with previous AW drive

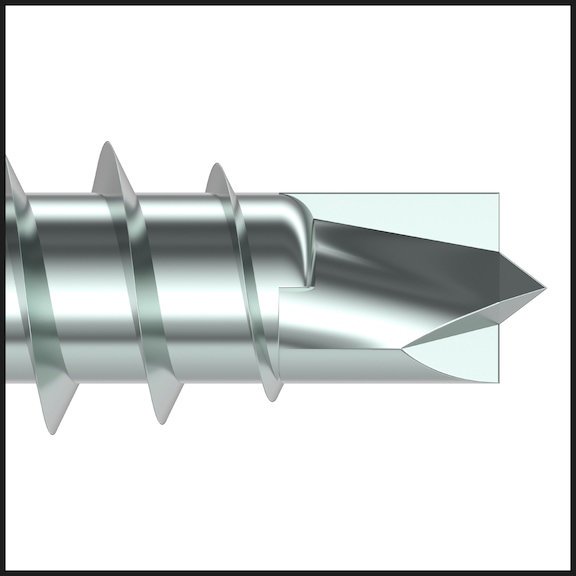

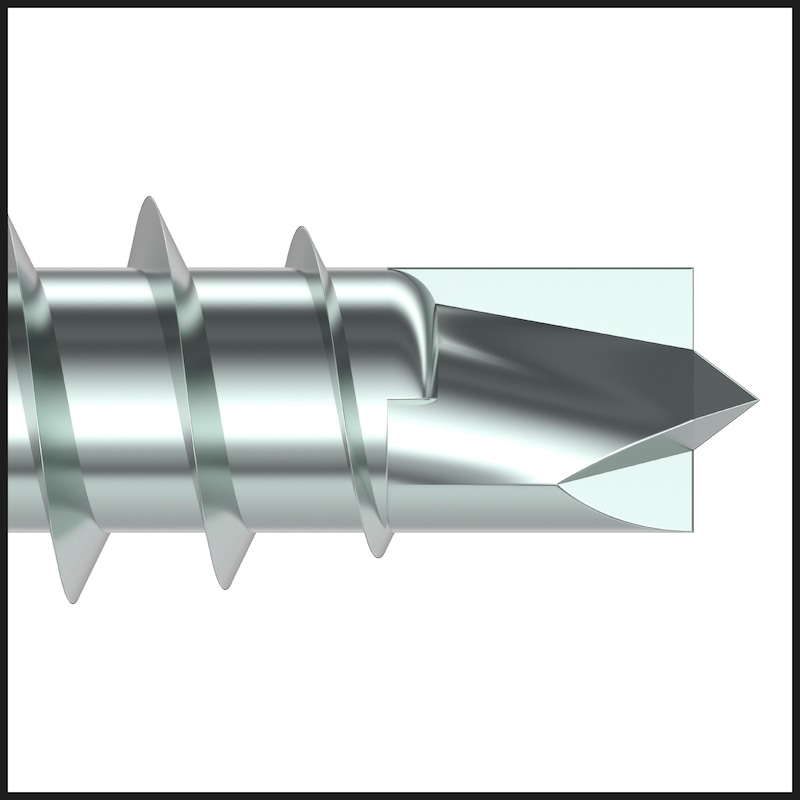

Precise positioning and very clean drilling due to advanced centring drill tip

- Positioning and drilling without chipping

- Maximum drilling performance and precise drilling process through drilling cutting edges (similar to Forstner bits)

- Precise positioning on hard surfaces without slipping thanks to centring pin

- Quick screwing due to gentle start of thread

Clean countersinking in softwood or wood material

- Easy countersinking of screw head in wood thanks to optimised milling pockets

- No chipping in coated chipboards due to improved milling effect and increased number of milling pockets up to ∅ 4.5 mm

- Perfect fit of 90° head in fitting parts with metal countersinks

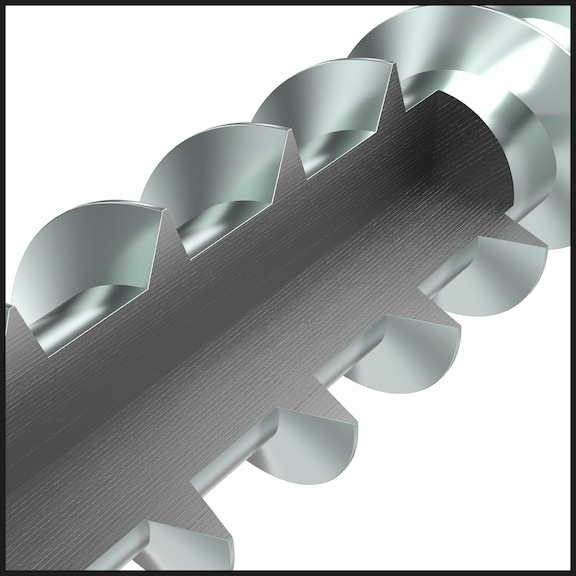

Maximum reliability of the screw connection due to asymmetrical single thread

- Optimal matching of drill tip and thread geometry

- Excellent anchoring in wood due to asymmetrical arrangement of thread flanks

- Do not use the screw in applications with direct exposure to the elements or in humid rooms with atmospheres containing chlorine gas. Please use ASSYplus 4 stainless steel screws for outdoor applications and rooms with constant high humidity

- We recommend using the Würth software or the corresponding design aids for planning and dimensioning your assembly. Use the Würth timber construction software for dimensioning of ASSY screws from a diameter of 5 mm

- ASSY 4, ASSYplus 4 and ASSYplus 4 FT chipboard screws are optimised for use in wood and wood materials. For applications in plastic anchors where load capacity can also be reduced, use only screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

ETA-11/0190 approved

The requirements of the European Technical Approval (ETA) must be observed.

For wood-wood connections designed to pull together

A wood-wood connection designed to pull together is possible owing to partial thread starting immediately after the shank. The thread in this case is positioned entirely in the lower second component.

For applications in utilisation class 1 and utilisation class 2 (from ∅ > 4 mm)

- High-quality surface protection zinc blue passivated chromium(VI)-free, up to ∅ 4 mm A2K 5 µm, from ∅ 4.5 mm A3K 8 µm layer thickness

- Suitable for use in utilisation class 1 (interior) and from ∅ > 4 mm in utilisation class 2 (wet area or covered outdoor area) according to EN 1995-1-1:2010-12 + DIN SPEC 1052-100:2013-08

- For screws from ∅ 4.5 mm with zinc layer thickness 8 µm with Cr(III) passivation, the requirement of classification T2/C2 is fulfilled in accordance with prEN 14592:2017 (D)

- To increase the joining effect or head pull-through resistance, combining with perfectly fitting washers for ASSY 4 is recommended

- For optimum use of the screw, the right-size RW bit must be used

- Partial-thread screws are ideal for connecting wooden components. To achieve optimum assembly of the components, the components to be fixed must not be thicker than the length of the shank

- If countersunk head screws are used for a metal-to-wood mounting, the metal to be connected must be provided with suitable countersunk holes

- For a load-bearing wood-metal connection, ASSY screws must be tightened to a specific torque value. Tightening torque = required prevailing torque x 1.2 < 90% of the breaking torque

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!