For detailed information, other images and documents, please select individual articles from the following table.

Register now and access more than 6,000 products

Variants

Register now and access more than 6,000 products

Paragraph

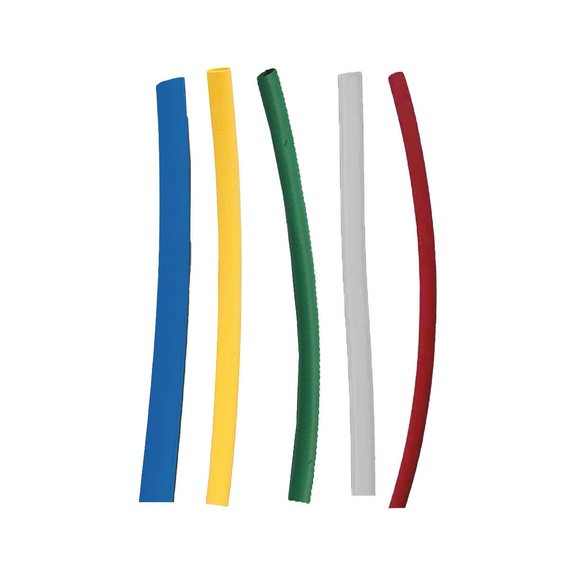

Coloured heat shrink tubing is an essential solution for professional cable management, offering both protection and visual identification in a single product. Designed from premium, flame-retardant polyolefin, it provides excellent electrical insulation, abrasion resistance, and strain relief in demanding environments. The range is available in a variety of colours to support clear circuit coding, reduce troubleshooting time, and enhance overall installation quality. Supplied in standard 5 m lengths and a range of diameters, it is suitable for automotive, electrical, and industrial applications, whether for new installations or repair work.

Key Features & Benefits

- Material: High-quality, flame-retardant polyolefin.

- Function: Electrical insulation, abrasion protection, and strain relief.

- Colour Options: Multiple colours for circuit identification and coding.

- Sizes: Available in various diameters to suit different cable gauges.

- Length: Standard 5 m rolls for flexible use and reduced waste.

- Performance: Resistant to wear, mechanical damage, and environmental exposure.

- Applications: Suitable for automotive wiring, industrial control systems, and electrical installations.

- Compliance: Meets common industry safety and performance standards.

Notice

Ensure the tubing size is correct for the application before heating. Avoid overheating, which may cause damage to the tubing or underlying components. Not suitable for direct contact with sharp edges or high-friction points without additional protection. Prior to installation, verify compatibility with the intended cable insulation and environmental conditions. The usage instructions are recommendations based on tests and experience; carry out your own tests before each application. Due to the wide variety of applications and varying storage and processing conditions, no liability is assumed for a specific application result. Where our customer service provides technical information or advice, no responsibility is assumed except where this falls within the scope of our specified, contractually agreed service or where advice is given deliberately. Product quality is consistent; we reserve the right to make technical changes and improvements.

Application Area

- Coloured heat shrink tubing is designed for a wide range of professional applications where cable insulation, protection, and identification are essential. It is widely used in:

- Automotive wiring and harnesses – providing abrasion resistance, strain relief, and colour-coded circuit identification for easier maintenance and troubleshooting.

- Electrical installations – insulating exposed conductors, covering soldered or crimped joints, and offering a neat, professional finish to wiring assemblies.

- Industrial control systems – protecting cables in machinery, control panels, and equipment while enabling quick visual identification of specific circuits or phases.

- Marine and transport sectors – guarding against environmental wear and tear while simplifying service work through clear colour coding.

- Repair and maintenance work – restoring insulation integrity on damaged or aged cable jackets and reinforcing vulnerable points against mechanical stress.

Suitable for both new installations and refurbishment projects, the tubing is effective in environments where durability, flame retardancy, and reliable performance are required. Its range of colours and sizes allows for custom-coded wiring layouts that improve safety, organisation, and efficiency in a variety of technical fields.

Instructions

Select the correct size

- Choose tubing with an internal diameter approximately 20–30% larger than the cable or component to be covered before shrinking.

Prepare the cable or component

- Ensure the surface is clean, dry, and free from grease, oil, dust, or loose particles to achieve maximum adhesion and insulation performance.

Cut the tubing

- Cut to the required length using a sharp blade or cable cutter, ensuring clean edges for a neat finish.

Position the tubing

- Slide the tubing over the cable, wire, or joint so it fully covers the area requiring insulation or protection.

Apply heat evenly

- Use a heat gun or suitable controlled heat source, keeping the nozzle at a safe distance to avoid scorching.

- Rotate or move the heat source evenly around the tubing until it shrinks tightly over the component.

Allow to cool

- Let the tubing cool and set before handling or putting the assembly under tension.

Inspect the installation

- Check for full, uniform shrinkage without gaps, bubbles, or burns.

- If required, repeat with a second layer for added protection or insulation.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!