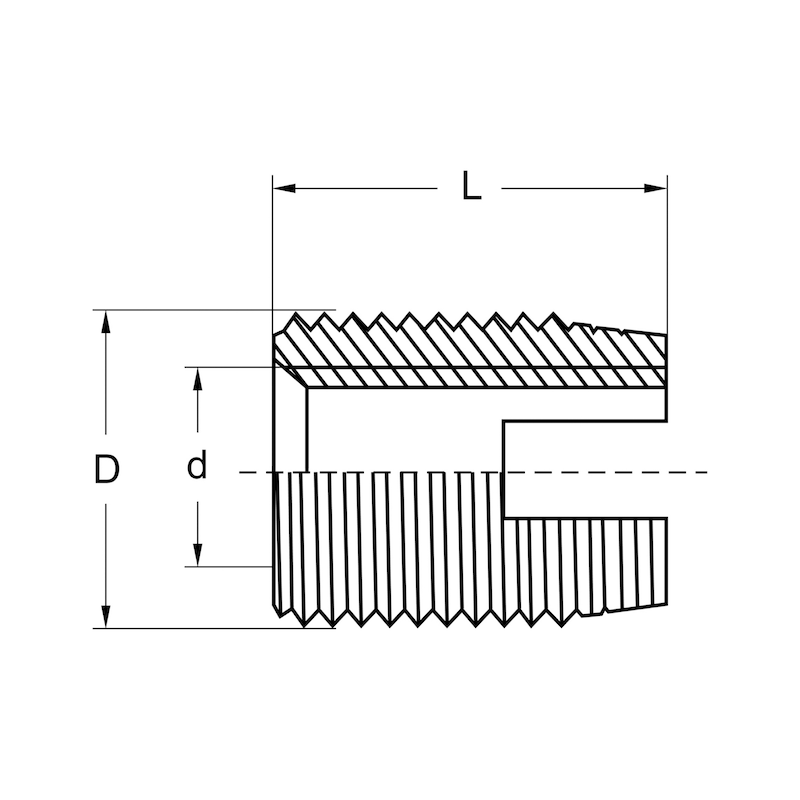

Self-tapping thread insert with cutting slot

For detailed information, other images and documents, please select individual articles from the following table.

Self-tapping thread insert with cutting slot

Saves time during thread repair and thread reinforcement

Exclusively for trade customers

Register now and access more than 6,000 products

Variants

Exclusively for trade customers

Register now and access more than 6,000 products

- For producing high-strength screw connections and other threaded connections in materials with low shear strength, e.g. cast iron, aluminium alloys, plastics, hardwood etc.

- The inserts are simply screwed into a pre-drilled or pre-cast hole

- Cutting effect due to sharp edges and interrupted threads of the male thread

- The front threads are bevelled for easier cutting and insertion

- The cutting slot keeps the thread inserts anchored even during strong vibrations or shaking of the workpiece.

- Chrome(VI)-free zinc thick film passivation for good corrosion protection (corrosion resistance in salt spray test according to DIN EN ISO 9227-NSS (h): 72h white rust/120 red rust)

Application area

- Applications in the entire metal and plastic processing industry

- Thread reinforcement on tools with low shear strength, e.g. cast iron, aluminium alloys, plastics, hardwood etc.

- For repairing torn-out threads

- Usual applications:

- For light metals and metals with a strength up to approx. 400 N/mm²

- For cast iron with hardness up to approx. 220 HB

- Plastic and fibreglass-reinforced plastic

(Tests on the original component are recommended, particularly near edges.)

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!