For detailed information, other images and documents, please select individual articles from the following table.

Chemical injection mortar Basic WIT-PM 200

Base mortar for masonry and uncracked concrete

Register now and access more than 6,000 products

Variants

Register now and access more than 6,000 products

Call customer service: 0800116633

Prices for customers after login

Two-part reactive resin mortar, styrene-free polyester

Individual fixing point in uncracked concrete:

Anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1

Individual fixing point in masonry (system with perforated sleeve SH):

Anchor rod W-VI-A, standard threaded rod with acceptance test certificate 3.1, perforated sleeve SH

- European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance certificate 3.1)

- European Technical Assessment ETA-13/0037: Individual fixing point + masonry (anchor rod W-VI-A, standard threaded rod 3.1, perforated sleeve SH, aerated concrete only without perforated sleeve)

Wall units

Wall units

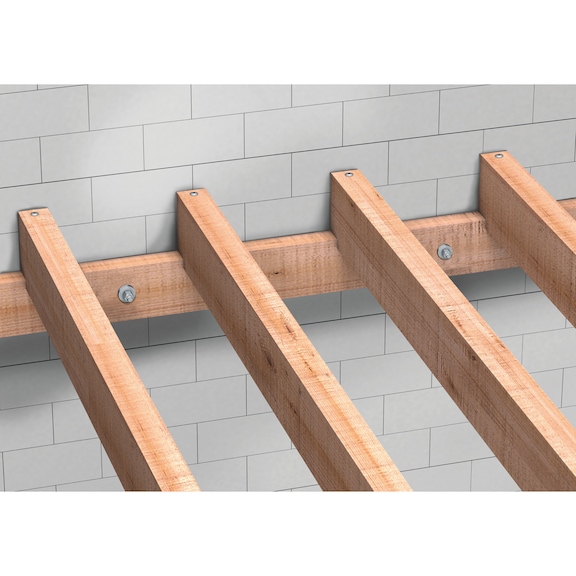

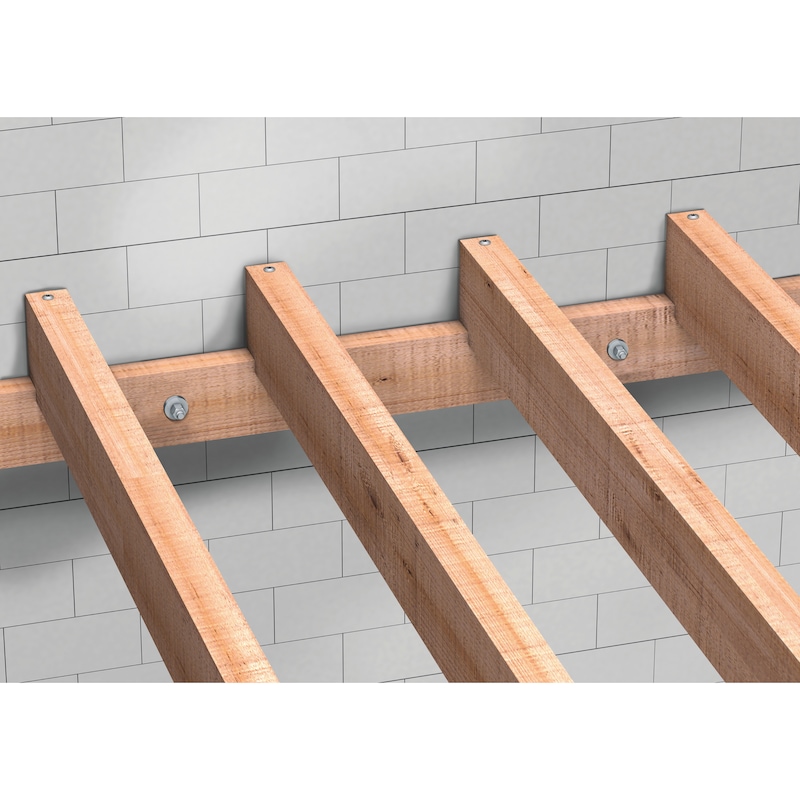

Wooden structures

Wooden structures

Stairs

Stairs

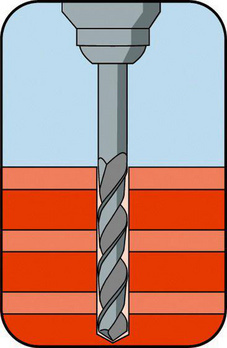

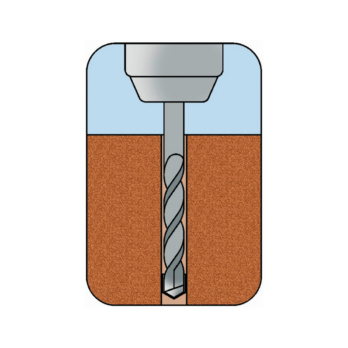

Drill holes with a rotary drill (without impact mechanism)

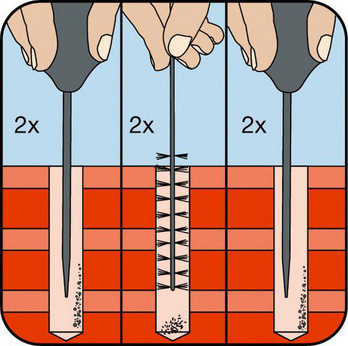

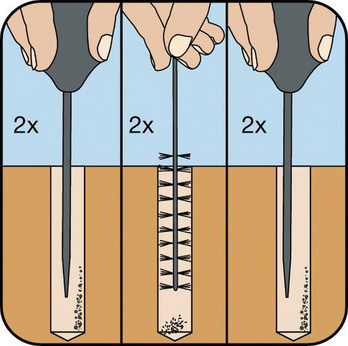

Clean drill hole; 2x blow out/2x brush out/2x blow out

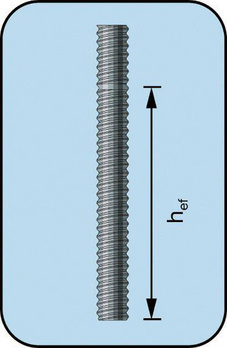

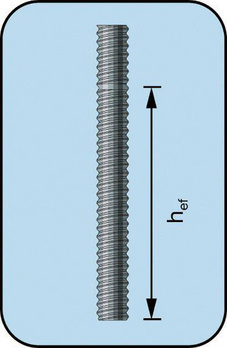

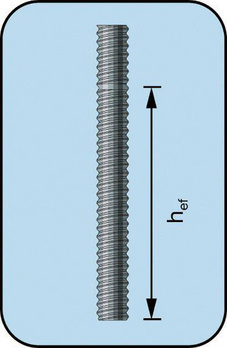

Cut anchor rod to length and mark the desired insertion depths

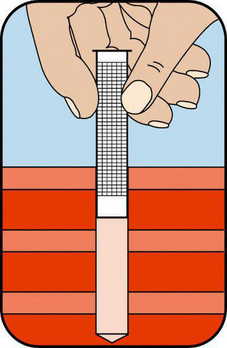

Insert sieve bush

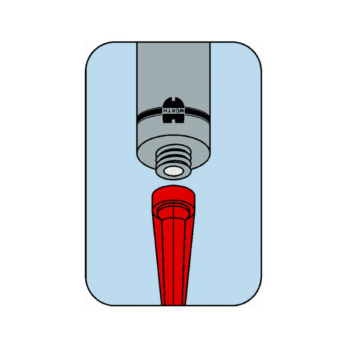

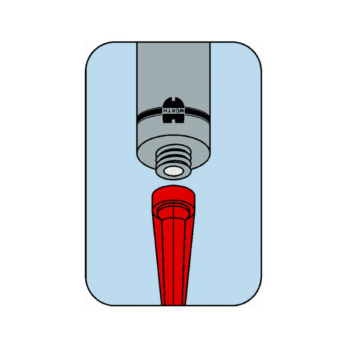

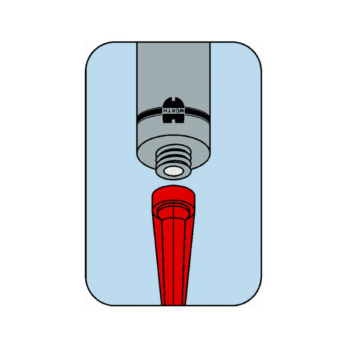

Screw mixer onto cartridge

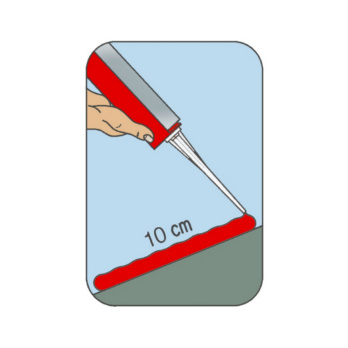

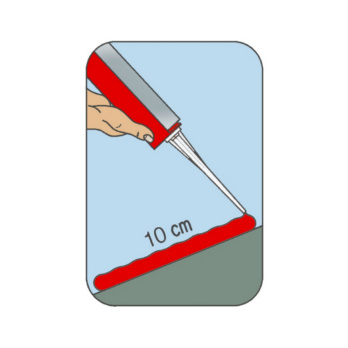

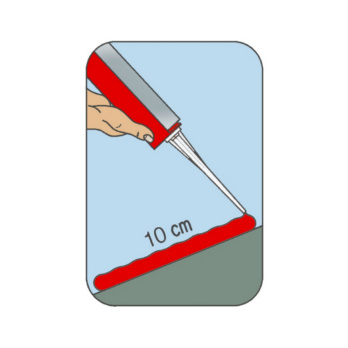

Before use, press out approx. 10 cm cord

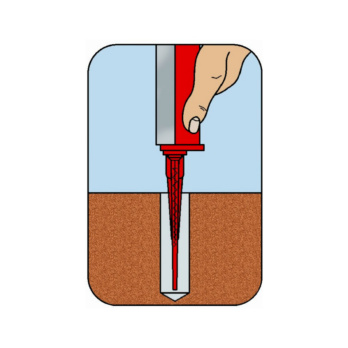

Completely fill with composite mortar from end of perforated sleeve

Press in anchor rod up to the bottom of the sleeve while turning slightly

Comply with hardening time of composite mortar

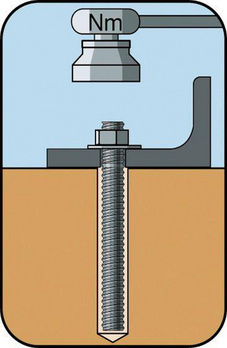

Install component, max. torque must not be exceeded

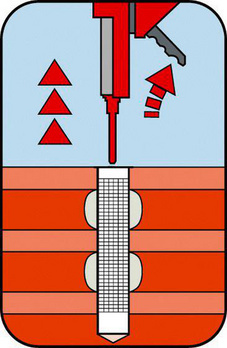

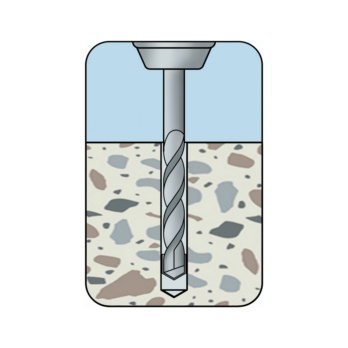

Create the drill hole

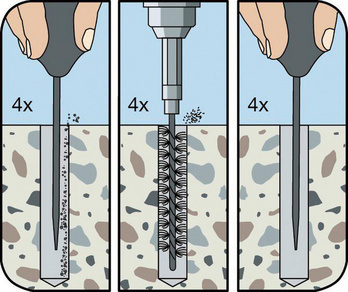

Clean drill hole; 2x blow out/2x brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord

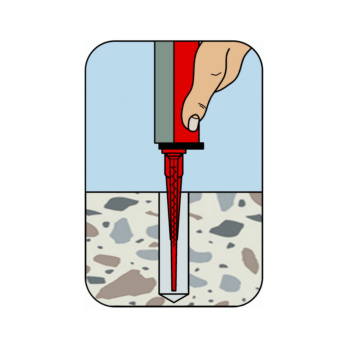

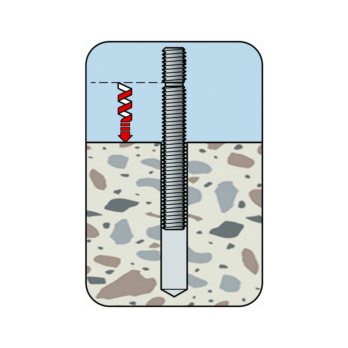

Fill with composite mortar starting from drill hole base (see enclosed leaflet)

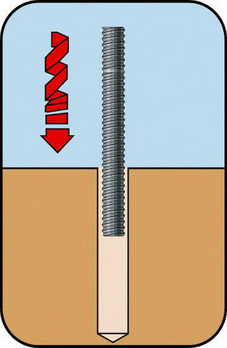

Press in anchor rod up to the bottom of the sleeve while turning slightly

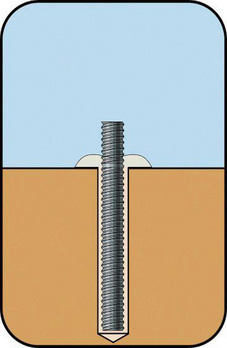

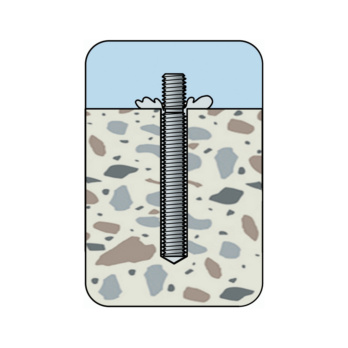

Visual check of mortar volume, embedment depth mark

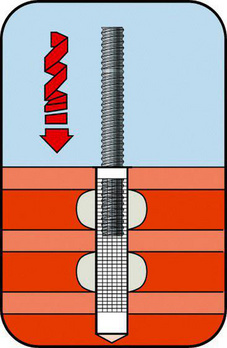

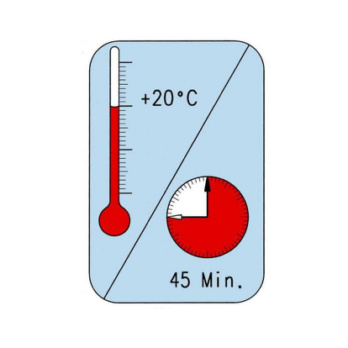

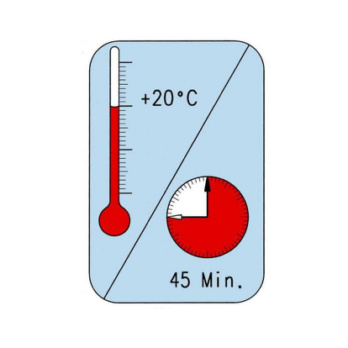

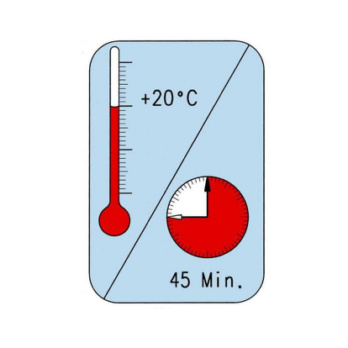

Comply with hardening time of composite mortar

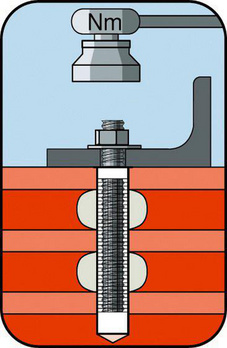

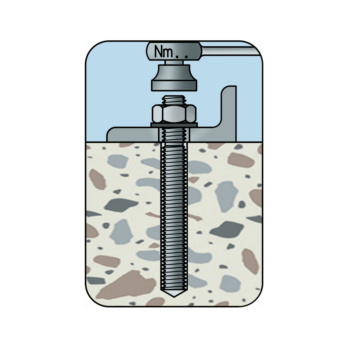

Install component, max. torque must not be exceeded

Create the drill hole

Clean drill hole; 2x blow out/2x brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord

Fill composite mortar from bottom of drill hole

Press in anchoring element up to drill hole base while turning slightly

Visual check of mortar filling quantity, setting depth marking

Comply with hardening time of composite mortar

Install component, apply installation torque

- European Technical Assessment ETA-12/0569: Individual fixing point + uncracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance certificate 3.1)

- European Technical Assessment ETA-13/0037: Individual fixing point + masonry (anchor rod W-VI-A, standard threaded rod 3.1, perforated sleeve SH, aerated concrete only without perforated sleeve)

- Attachment in uncracked concrete, solid and perforated brick masonry, aerated concrete

- Suitable for attaching wooden structures, metal structures, metal profiles, brackets, grilles, sanitary ware, pipes, cable conduits, etc.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!